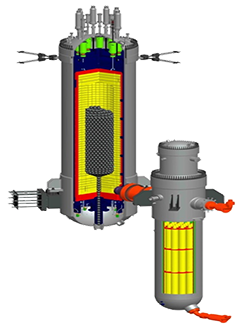

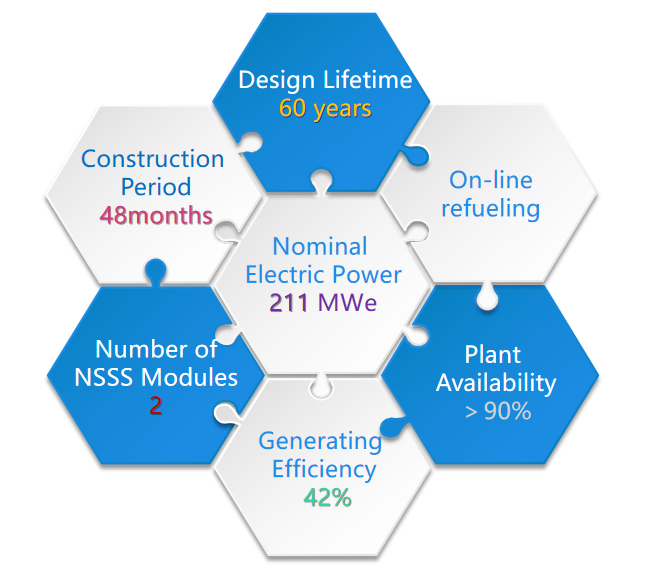

The Pebble-bed Modular High Temperature Gas-cooled Reactor (HTR) is the advanced Generation IV nuclear reactor with independent Chinese intellectual property. It features with inherent safety, simplified system, modular design and construction, high power efficiency, multiple applications and on-line refueling. And those outstanding features make the HTR incredible in inherent safety and largely avoid core meltdown and radioactive release.

Helium as coolant

Graphite as moderator

High Temperature at reactor outlet

Complete Chinese independent intellectual property nuclear technology with Generation IV characteristics.

It features with inherent safety, modular design &construction and multiple applications.

Flexible plant capacity of 200MW, 600MW, etc.

Fundamentally eliminates the possibility of reactor meltdown and radioactive substance release.

Impossible to exert any negative effect on human health and environment under any circumstance.

Technically, HTR does not need off-site emergency, can be built near the large-populated area, even surround the city.

Shutdown Systems

Shutdown SystemsTwo independent reactivity control systems: control rod system and absorber ball system. During accident conditions, these two systems can be actuated automatically, to compensate the positive reactivity induced by the accident without any manual action.

Negative Temperature Coefficient

Negative Temperature CoefficientFull range negative temperature reactivity coefficient: inherent safety features under accident conditions. The reactor can be shut down automatically by large negative reactivity in case of anticipated transients without scram(ATWS).

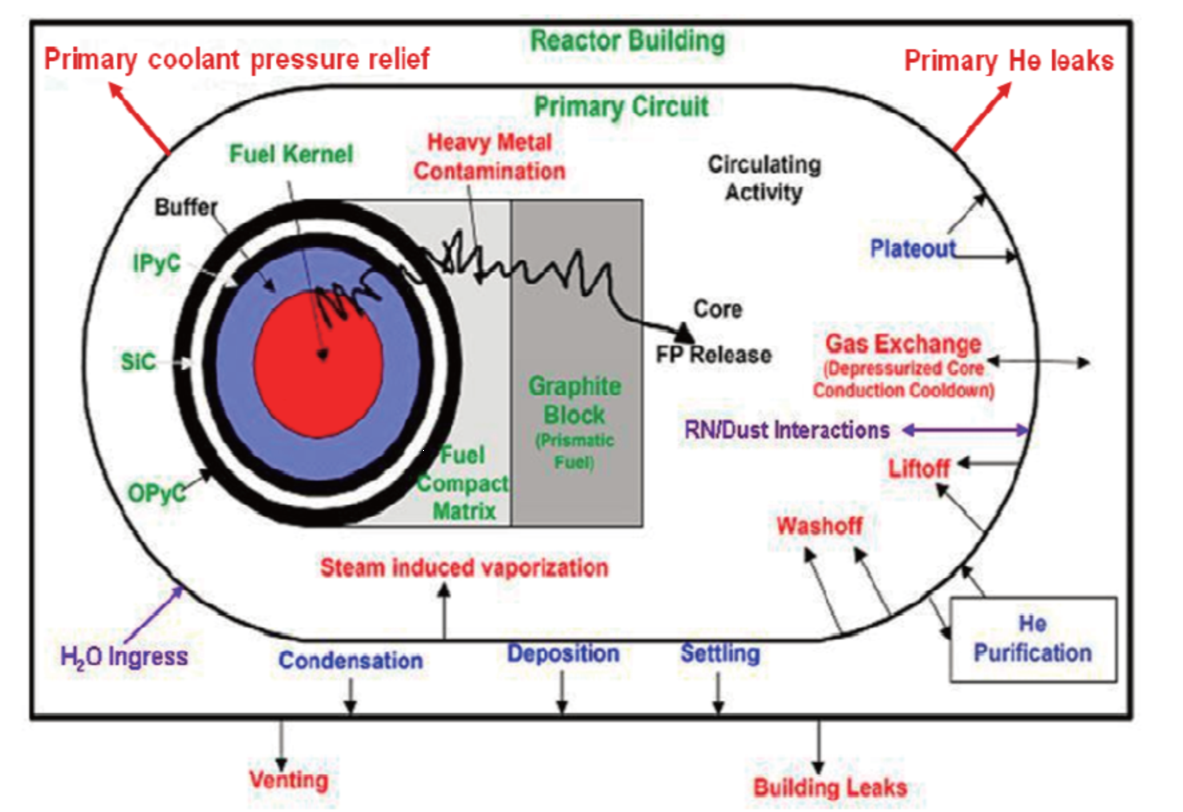

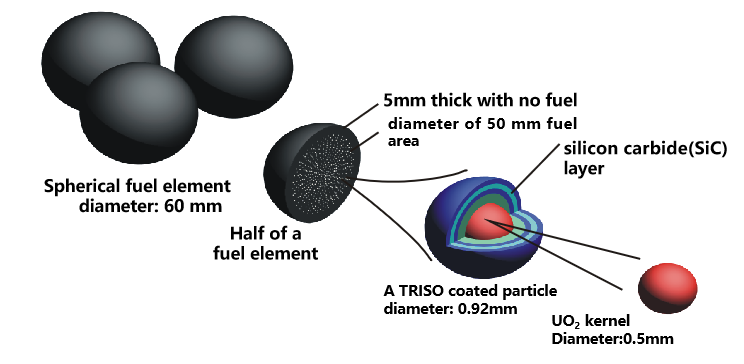

Treble barriers preventing the release of radioactive isotopes: Coated Fuel Particles, Primary Pressure Boundary and Containment.

Most important barrier: SiC layer of coated particles can bear 1620℃,however the highest temperature on the fuel elements occurs 1530℃ even the ATWS conditions.

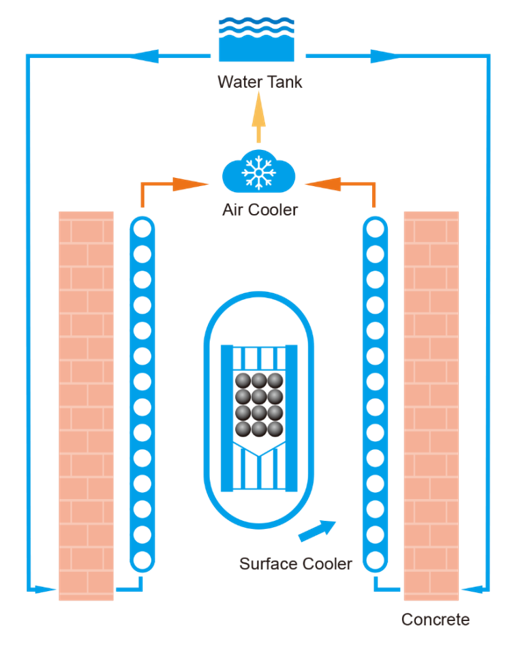

thermal transmission, convection & radiation

natural circulation

110MW per module

2 modules in 1 reactor building

Connecting with 1 turbine to form a 220MWe unit

110MW per module

6 modules in 1 reactor building

Connecting with 1 turbine to form a 660MWe unit

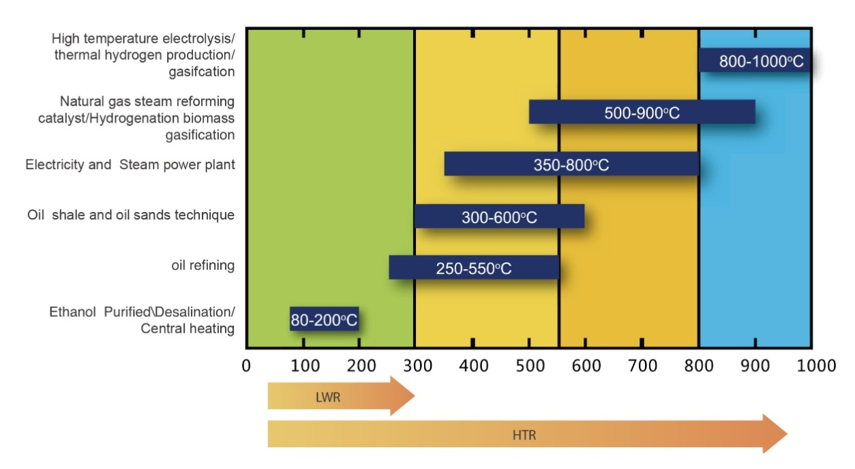

In the future, the steam outlet temperature can reach up to 1000℃ to form clean heat source which can be applied in

coal gasification & liquefaction and thermochemical hydrogen production with great industrial prospect in energy system.